ZF – a well-known supplier of transmissions and related components in the agricultural tractor and machinery world – is never far from toying with new “innovations”.

Among its more interesting “inventions” is its so-called Innovation Tractor.

Its big claims to fame are “fingertip maneuverability and easy connection” of implements (SafeRange and Hitch Detection). It also has the apparent “ability to overcome any gradient” (with a tractor-trailer combination), thanks to an additional electric-drive unit.

The Innovation Tractor first appeared in 2016; work is ongoing on the system.

So what does it entail? First up is SafeRange; it can be used to remotely control a tractor when, say, coupling a trailed or mounted implement.

All the relevant driving and steering commands can be given using a tablet. A total of six cameras on the rear and roof of the tractor provide the necessary visual information of the surroundings.

With the Hitch Detection feature, the Innovation Tractor uses a camera to detect the exact position and angle of the implement or trailer, and automatically controls the tractor’s approach.

For safety, the process is interrupted if a person “appears” between the tractor and implement.

Meanwhile, an electric wheel-motor (developed specifically for use in agricultural and construction machinery) can be incorporated into a trailer being towed by the Innovation Tractor.

Also Read: Can this electric ‘wheel assist’ get you an extra two furrows?This (all-electric) additional drive-unit is supplied with power from a generator module (within the ZF TERRA+ transmission system) on the tractor. It can churn out up to 60kW – when needed.

The aim is to boost traction when, for example, hauling a heavy load up a steep incline.

ZF’s roots

ZF originated as a supplier that specialised in transmission components for the aviation industry; it later morphed into what it describes as “a global mobility technology company”.

Back in 1915, Alfred Colsman (then the general manager of Luftschiffbau Zeppelin GmbH) described the events that led to the establishment of ZF.

‘Best gears in the empire’

In fact, he declared that the founding members had the “best gears in the German empire“.

He explained: “As long as power from the engine in the Zeppelin vessels [the famous airships named after German Count Ferdinand von Zeppelin] was transferred to propeller reduction units by means of long steel shafts, the noise was almost unbearable.

“Count Soden, who managed the testing department at Luftschiffbau Zeppelin and concentrated on transmission issues, one day revealed the news that a Swiss engineer by the name of Max Maag had succeeded in manufacturing mathematically accurate gears.

Gears ground on Maag machines could potentially reduce transmission noise and increase safety, which is why I entered into licensing negotiations with Maag Zahnrader AG in Zurich.

In the course of ZF’s establishment, which took place on August 20, 1915, under the name of ‘Zahnradfabrik GmbH’ (with headquarters in Friedrichshafen), Colsman and Soden were able to secure the exclusive licence in Germany for the distribution of these gears and transmissions (in accordance with the Maag system).

https://www.youtube.com/watch?v=WkmvpUa2A20

With this, ZF had a ‘unique selling proposition’. From there, the business grew (expanding into the motor vehicle and motor boat sectors, when the airship sector encountered a major crisis after the end of the first world war).

First tractor trans-axle

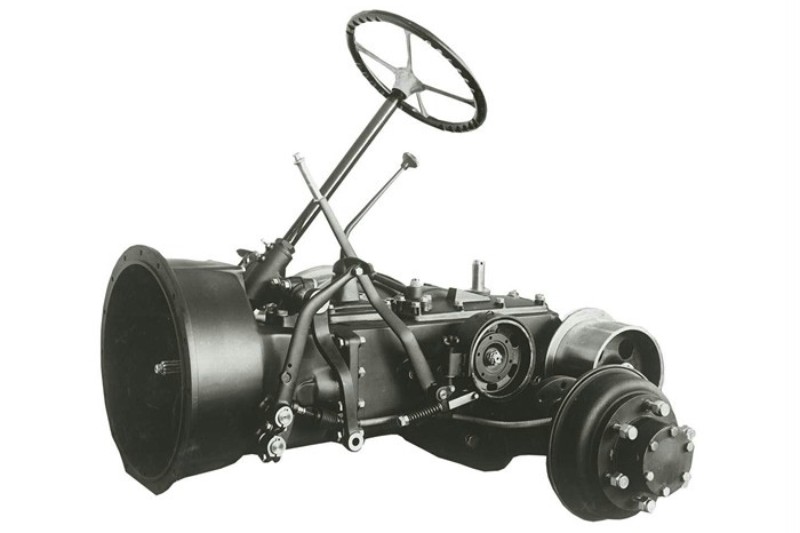

Fast forward to 1937; that’s when ZF engineers designed a tractor trans-axle comprising a transmission and rear-axle drive in one product.

That ‘universal transmission’ (pictured below) was known as the A12.

It was suitable for tractors with engine outputs of up to 22hp. It was the fore-runner to a whole family of later tractor trans-axles; it was an important product for the company.

It was suitable for tractors with engine outputs of up to 22hp. It was the fore-runner to a whole family of later tractor trans-axles; it was an important product for the company.

Nowadays, ZF builds all manner of tractor trans-axles, including CVT (Continuously Variable Transmissions) units for tractors of up to 650hp.