With slurry restrictions now lifted for the majority of the country and evenings begin to stretch ever so slightly, slurry tanks will be getting busy again.

Many farmers may have already spread a bit to take off storage pressure, but the real workload is going to increase significantly in the coming weeks.

That means farmers and contractors must concentrate on getting the tanks in perfect working order before the busy period.

But what are the main aspects to focus on when servicing the machine?

Servicing the slurry tank

If farmers are under a time crunch, especially with their own machines as spring calving kicks off, they should still try and carry out general tasks such as greasing all the nipples and checking to ensure the tyres have the correct pressure for travelling in marshy conditions.

Check to see if the brake lights, indicators, and beacons are working before taking to the road.

It is also crucial to look at the PTO shaft and the cover to make sure everything is in proper working order before hooking up.

If you do have the time to give a full look over the machine, then it’s advisable to do so, as the time you will spend on it now will save you mountains of time come the busy season.

One of the essential tasks to carry out before spreading the bulk of your slurry is ensuring the vacuum pump’s oil is topped up, something that should be checked regularly throughout the season.

This oil in the vacuum pump keeps the whole tank in working order, and without it, the vanes inside the pump will swell, meaning they can no longer slide in and out of the slots in the rotor, ultimately locking up the pump and breaking the vacuum.

The vacuum pump oil should be checked using the dipstick on the side of the pump, while the oil lubricating the pump can be checked by watching the oil dropper on the tank.

Ideally, the oil should be dropping at a rate of one drop per second, but this often ends up being quicker when the oil heats up, so sometimes it takes a bit of adjusting.

The last oil to check is the gearbox oil; ideally this should be drained and replaced as you would with a car to keep everything running smoothly.

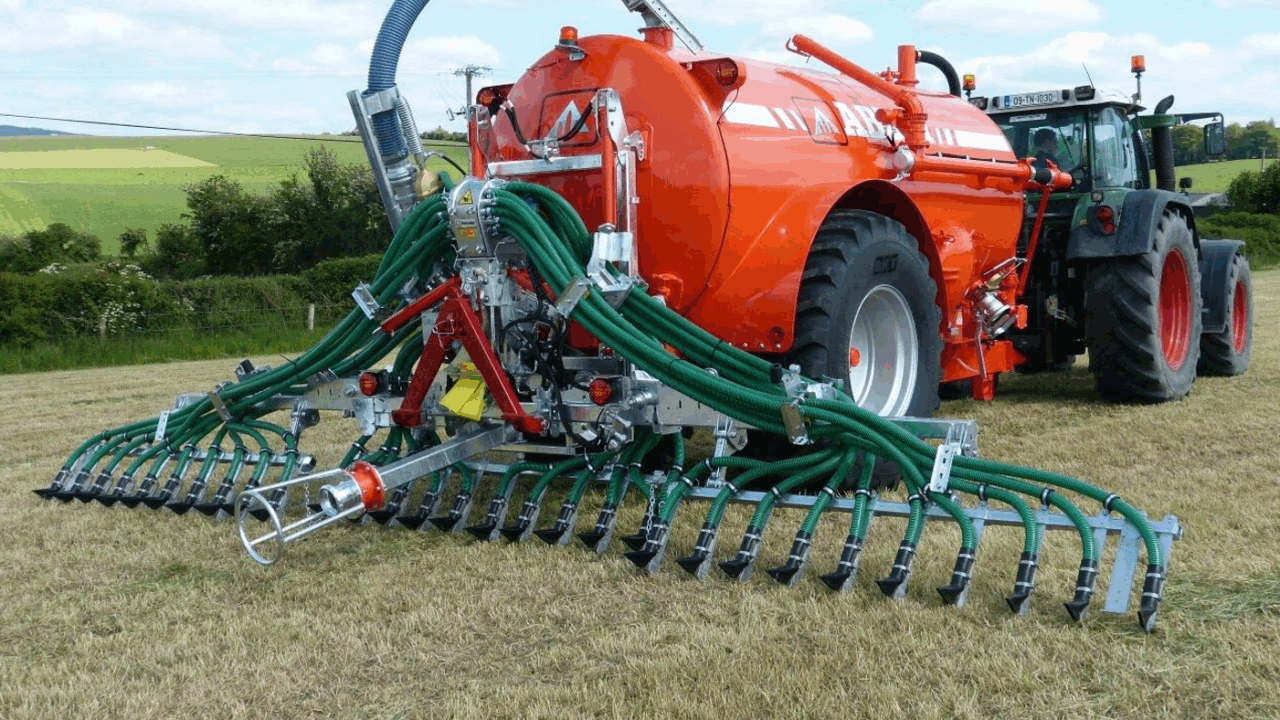

Dribble bar

Another task is to give a once over to your dribble bar/trail and shoe too, greasing any relative points and checking for any blockages.

Further maintenance includes checking the macerator for blade wear or blockages, as well as servicing it similarly as you would with the vacuum pump by checking/changing oil, and greasing any nipples.

If the slurry distribution is uneven, the outlets on the macerator screen may be blocked or the breather pipes on the macerator may be blocked, therefore the macerator needs to be purged out with water and the pipes and outlets must be checked and unblocked if necessary.

If this does not work, the problem may lie in the density of your slurry itself or there may be deeper issues with hydraulic pressure or the functionality of the macerator.

Maintenance

All seals on the tank, whether that be at the filling and spreading points or the pump and macerator need to be double checked to ensure that they are kept air-tight.

Some more tasks includes loosening the screws and removing the viewing glass, and cleaning it to see the tanks fill level.

The fill point handle of the rear/side filling points can often become loose, so they may need to be tightened by the nut on the top of the handle.

The tanks stone trap should ideally be emptied also.

One final thing to do is to ensure the slurry tanks pipe is free of cracks or damage.

Remember to always have slurry safety at the forefront of the mind; disconnect the tank or turn off power completely before carrying out any of these tasks.