Derick, Sylvia and Hall Donnell farm 73ha beside Ballymogorry village, just north of Strabane in Co. Tyrone.

The farmyard is centrally situated, with approximately 39ha around the yard and the remainder in outlying farms.

The family has been milking approximately 100 Holstein-Friesian cows since they took over the farm in 1989. In 2011, they installed a 14-unit, 90-degree Milfos swingover parlour from McKnight Dairy Services.

A farm open day will take place on Wednesday, October 17 from 11:00am to 3:00pm on the Donnell family farm at Park Road, Ballymagorry, Strabane, BT82 0AN (signposted from the A5 in Ballymagorry village).

The cows were milked twice daily at 5:00am and 5:00pm, with an emphasis on grass production and feeding from mid-March until Mid-November, depending on annual conditions.

The farm objectives are to:

• Maximise overall farm profit;

• Have a labour-efficient working environment;

• Utilise forage from both grass and ensiled grass to its full potential;

• Make efficient use of nutrients (fertiliser and slurry) while meeting current nitrates legislation.

The new robot system

Robotic milking was always a plan in the background for the Donnell family and, when a 12,000l GEA tank was installed in 2012, it had to be robot ready.

“Last year we considered upgrading the out-of-parlour feeders and contacted our local dealer McKnight Dairy services.”

After a few visits from dealers, James McKnight and Roy Clarke of GEA Ireland, “the option of going ahead with robotic milking looked more appealing with the introduction of the Monobox to Northern Ireland”.

The milk price was good and we could see the potential benefits to our farm objectives and lifestyle; but really, the cows made the decision.

“Yields were steadily increasing each year, from 7,200l in 2010 to 9,600l this year. Cows needed milking three times a day,” according to Hall.

Installation and training

The installation went according to plan. The design was supplied by GEA’s Declan Casey, who provides technical support in the local dealers.

“James, David and their team at McKnights do very tasty work and were very efficient with the installation,” commented Hall.

The open design of the Monobox, along with the silent operation and quick attachment, made the start-up easier than expected.

“For two days we penned the cows behind the robots and guided them. Over the next two weeks, the number of cows we needed to collect dropped every day,” according to Hall.

The grazing block around the yard is divided by a public road and an underpass was not an option due to water levels. A grazing plan and layout was designed by GEA to allow cows to access grass for 16 hours on a daily basis on approximately 20ha and eight hours at the feed fence, depending on the time of year and weather conditions.

After two weeks, cows were allowed access to grass using a selection gate. Cows have access to Block A from 2:00am to 10:00am (after they have been milked). Then, as they return for a second milking, they are rewarded with fresh grass in Block B from 10:00am to 6:00pm.

Any cows that come in after 6:00pm can access feed at the feed fence and stay in for the night.

“Allocation of grass is very important to encourage cows to move voluntarily. May was a difficult time to start this year with a big flush of grass; but once I got used to the new allocation, and we got around the block a couple of times, the cows were coming really well – with no cows to collect since mid-Summer,” remembered Hall.

Hall’s top three benefits for the herd:

- “Now the cows are milking three times a day; they are carrying less milk and not waiting around to be milked. I have noticed an improvement in legs and lameness.

- “Cell counts always ran around 150 over the last few years. For the last few months, we are down around 90; it has increased slightly recently as cows are due for drying off. The conductivity is so accurate it allows me get in early and treat with udder mint; the Monobox also allows me to separate per quarter, giving me more control.

- “In the last couple of weeks when I started drying off cows, I noticed a huge improvement in teat condition; they are soft and healthy looking and there are no signs of warts or cuts on them. The cows temperament has changed; they are quieter to work with.

Hall’s top three benefits for himself:

- “I don’t set the alarm anymore; in the morning, I just get up when I wake.

- “I had a lot of work to catch-up with after the start-up, and we are building the separation area; but it’s amazing how much more time I have.

- “The flexibility is great if I’m at silage or spreading slurry. I don’t have to stop to get cows in and can just carry on and get the job finished.

Hall’s future Goals:

- “1 million litres from 100 cows or less.

- “We currently use sex semen on between 22 and 24 cows each year for replacements. And then run the stock bull. I might start to breed some more heifers, as there is a good demand for our stock at the minute.

- “Continue to enjoy farming.”

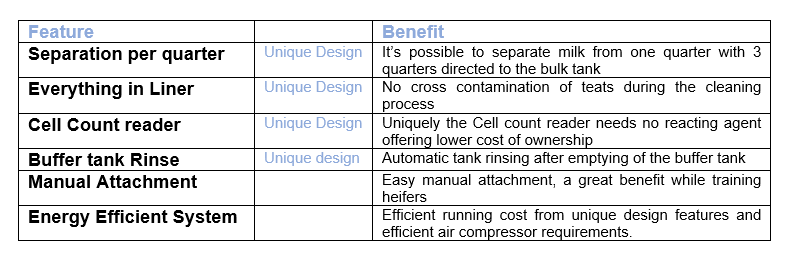

Features and Benefits of the Monobox

On behalf of the Donnell family, we would like to thank you all for your kind donations to their charity. We would also wish to extend our thanks and appreciation to the Donnell family for opening their farm to the public to showcase the new GEA Monobox system – the latest in robotic technologies.

To find out more about the GEA Monobox click here